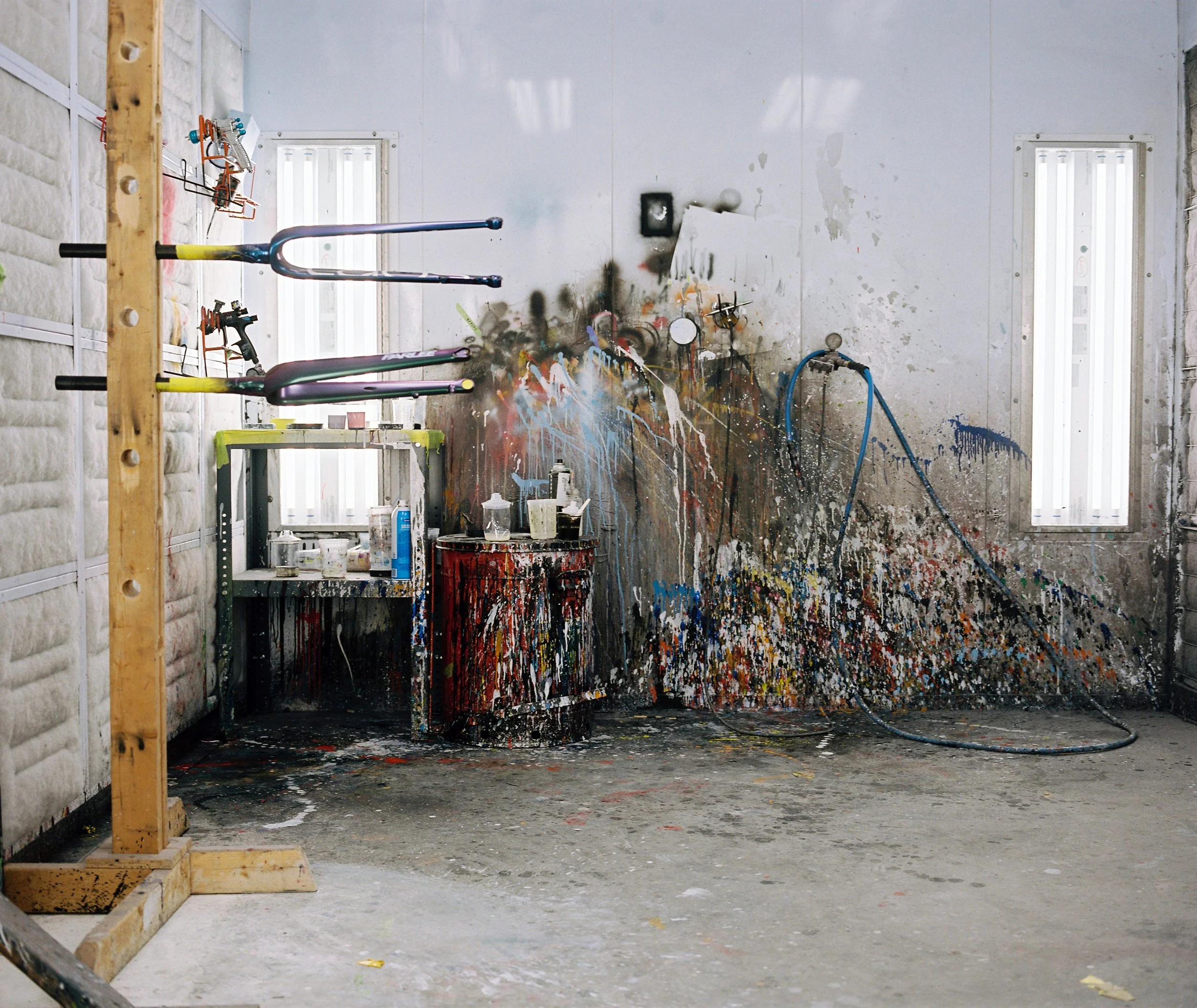

Cody Haight — Paint

Evolution | Parlee

“This is very much a dream job. We’ve always offered full custom paint straight from the factory—whatever your heart desires. Very rarely do we tell someone no. When I see one of my bikes out in the world, it’s still kind of surreal. Bob and Isabel built something that felt like a family, and everyone here is just happy to carry that forward.”

Cody Haight is Parlee’s painter and one of the longest-serving members of the team. He joined the company in 2010 straight out of high school. Haight is responsible for Parlee’s factory-direct custom paint—an increasingly rare offering that allows customers to engage directly with the final expression of their bike. In our conversation, Haight reflects on process, pride, and what it means to spend a decade and a half at Parlee.

Your role and what brought you to Parlee?

My name is Cody Haight. I’ve been the painter at Parlee for 16 years now. I got the job while I was still a senior in high school doing collision repair. A lot of the painters came from there. They went back looking for a new painter, plucked me out of high school, and I’ve been here ever since. I’d probably say I’m the third longest one here. I think Tom and Rommel—the bike builder—are one and two.

Your background was auto painting and collision repair. How does that translate to bikes?

A lot of the paint techniques transferred over. It’s a different beast doing custom work versus matching colors, but that’s why I got into bicycles instead of staying in cars. I like the custom aspect. I enjoy doing the fun paint jobs.

When I first started, I was taught by my manager, Brian Burke. Before he left, he had been here around 13 or 14 years. So I had a very experienced painter teaching me as I came in.

When I first started, the custom paint jobs weren’t as crazy. They’ve gotten crazier and crazier over the years as people learned what we can do.

Do you feel like the custom paint world is competitive? Trends? Technique?

It follows trends. A couple years ago everyone was all about neon. Now it’s more subtle—lots of blues. When COVID happened, people took time and came up with crazy ideas for us to paint. During the shutdown we did a lot of honeycomb paint jobs, a lot of masking.

Walk me through the Parlee process. If I order a bike with custom paint, what happens—from order to delivery, specifically your part?

It depends on the option, but typically if it’s a ZZero: I get it from Rommel and Lyndall upstairs—sanded and prepped—after the customer talks to Nate or Cary.

Then I receive the frame and put down a base layer to make sure everything’s good. I work off a paint render from one of our designers. They work with the sales guy to make sure everything’s right. I’m always around to check things, talk through it, make sure it works in real life.

From there it’s building up the files on my computer—logos, placement, everything how it needs to be—then we start painting. That’s when the fun starts.

In the paint process itself, where does the time really go?

Honestly, painting is usually the least amount of time I spend. Most of it is masking and measuring and making sure everything’s right. Actually spraying paint is the smallest part.

What’s distinct about Parlee’s approach to paint?

Since I started here, we’ve always offered full custom paint from the factory—whatever your heart desires. We very rarely tell someone no, unless it’s copyright or something that can’t be done.

We’re definitely one of the few—if not the only—brands where straight from the factory you can get your bike fully custom. And I think that’s always resonated with Parlee: it’s for the customer fully.

Do you meet customers? Do you ever see your work in the wild?

I run into people around town riding bikes I painted and we’ll have a conversation. It’s pretty amazing.

It’s funny—my fiancé gets shocked to see I have fans and that people know my work.

Any memorable paint jobs—favorite, wildest, most insane?

Back in the day my manager used to warn me: never paint samples you wouldn’t want to paint on an actual bike.

I didn’t listen. I ended up having to airbrush like 10,000 squares on a bike because I thought it was a good idea. I really liked it, but I would not want to do that paint job again.

What are you excited about right now—technically, aesthetically, product-wise?

In the last year, having the new Ouray and Taos be raw carbon—that makes me really excited. It opens up paint possibilities.

And the GT work has been amazing. When I started it was all mechanical and external routed bikes. Now it’s internal routing, Di2. It’s nice not dealing with cable routing around paint jobs. It gives you more freedom—like honeycomb. You don’t have to wrap patterns around external routing; you can get a smoother finish. It’s fascinating to see the leaps.

I remember when Parlee made a Prius bike years ago—we were on Good Morning America—because you could shift gears with your mind! So yeah, it’s been amazing seeing how everything progresses.

Raw carbon as a canvas—what does it enable, and what does it demand?

If we’re showing carbon, if there’s anything wrong with it, you really can’t hide it. But it gives you opportunities too: clear coat it and let the carbon show, or hit it with a candy—like candy blue—so you still see the weave but with a tint.

And honestly, even raw carbon with no paint—it looks amazing. It shows off our work. It helps show off all the hard work everyone puts into it.

You’re a North Shore guy. Does it mean anything to be doing this here—Massachusetts—where these bikes are made?

Yeah. This is very much a dream job. I enjoy knowing people are out there riding my bikes.

I have a hard time calling myself an artist, but a lot of people consider me one. That’s a weird disconnect. I was never the best art student. But I took to painting, and I’ve always loved the custom paint world. Put a paintbrush in my hand and I’m not very good. But this—this I love.

What’s the team dynamic like? What’s special about the group?

It’s always been great. Bob and Isabel were amazing to work with. They never made you feel anything less than family.

We’ve carried that mentality: you come to work at Parlee, you become one of us. Bob and Isabel created an amazing company, and I think everyone here is just happy to carry it on.

Parlee is a high-performance bicycle manufacturer headquartered in Beverly, Massachusetts.

Written by Chessin Gertler with Cody Haight | Photography by Chessin Gertler